HIGH-END LABS AND MILLING CENTERS LOVE THIS PREMIUM DENTAL MACHINE.

The CORiTEC 650i PRO series is ideal for high-end labs and milling centers that have high quality standards and also manufacture large quantities. State-of-the-art industrial technology makes this possible! Contact us now and get a free quote.

HIGH-END LABS AND MILLING CENTERS LOVE THIS PREMIUM DENTAL MACHINE.

The CORiTEC 650i PRO series is ideal for high-end labs and milling centers that have high quality standards and also manufacture large quantities. State-of-the-art industrial technology makes this possible! Contact us now and get a free quote.

Unique dental features:

Now available for the first time.

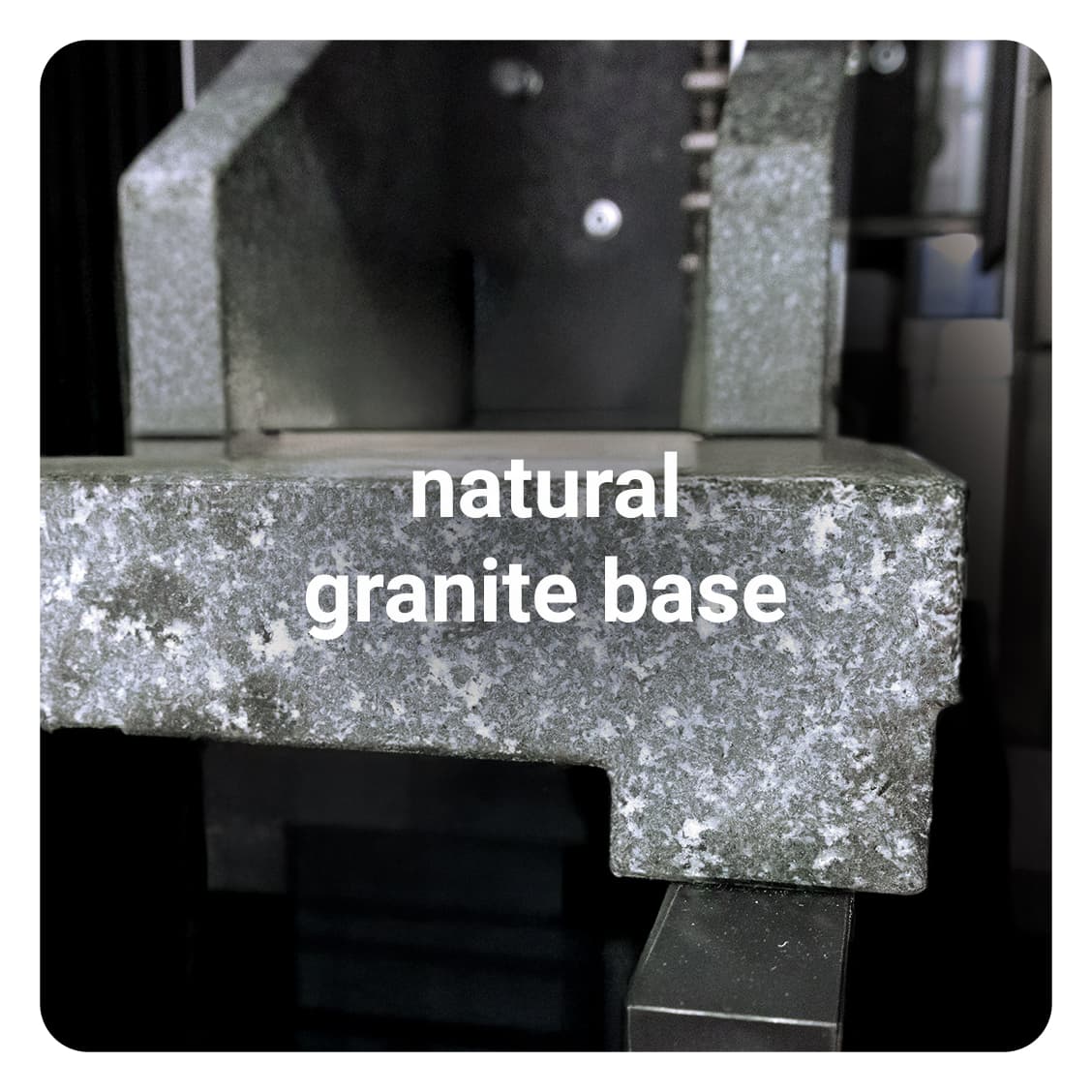

Natural granite as the foundation for excellence

Solid, polished natural granite guarantees absolute smoothness, extreme vibration damping, and thermal stability. For maximum precision, reproducible quality, and reliability – even under continuous load.

Intuitive operation on an industrial basis

Professional, open CNC control “iNC” on an industrial basis with touchscreen and intelligent assistants makes complex processes easier than ever before – maximum efficiency and the latest technologies without any training hurdles.

Unique dental features –

now available for the first time.

NEW: fully integrated turning and milling processing

Even complex components such as premilled abutments can be manufactured in up to 4 minutes. 360° rotating A-axis and a B-axis with an angle of up to 90° for maximum degrees of freedom and efficiency during processing.

Intuitive operation on an industrial basis

Professional, open CNC control “iNC” on an industrial basis with touchscreen and intelligent assistants makes complex processes easier than ever before – maximum efficiency and the latest technologies without any training hurdles.

This precision and power are world-class.

Unlimited performance: spindle power on a class of its own

The water-cooled 5.7 kW high-frequency spindle and 4-fold hybrid ball bearing combines power, stability, and durability – even the hardest materials are milled effortlessly. The high-precision HSK tool holder offers complete freedom in tool selection.

Enormous clamping force for uncompromising process reliability

With a clamping force of 5000 N, the EROWA zero-point clamping system holds every workpiece firmly and with repeatable accuracy (< 5 µm) – for reliable and fully automated production processes.

This precision and power are world-class.

Unlimited performance: spindle power on a class of its own

The water-cooled 5.7 kW high-frequency spindle and 4-fold hybrid ball bearing combines power, stability, and durability – even the hardest materials are milled effortlessly. The high-precision HSK tool holder offers complete freedom in tool selection.

Enormous clamping force for uncompromising process reliability

With a clamping force of 5000 N, the EROWA zero-point clamping system holds every workpiece firmly and with repeatable accuracy (< 5 µm) – for reliable and fully automated production processes.

| Exceptionally rapid milling times | |

| Excellent surface quality | |

| Perfect precision |

![]()

Insider insights: Now on YouTube!

Insider insights: Now on YouTube!

Insider insights: Now on YouTube!

1/10: CORiTEC 650i PRO series

Topic: Maximum precision for high-end-milling centers

Continue on YouTube

Milling around the clock –

high quality.

The CORiTEC 650i Loader PRO includes a fully integrated automatic 16-fold blank changer and a 32-fold tool changer. This allows the machine system to operate at full capacity around the clock without supervision, while maintaining consistently high precision.

The machine concept impresses above all with its precise, vibration-free, and dynamic movements in demanding and complex metalworking. All other relevant materials can also be milled or ground to a high quality on this machine system.

Milling high quality around the clock.

The CORiTEC 650i Loader PRO includes a fully integrated automatic 16-fold blank changer and a 32-fold tool changer. This allows the machine system to operate at full capacity around the clock without supervision, while maintaining consistently high precision.

The machine concept impresses above all with its precise, vibration-free, and dynamic movements in demanding and complex metalworking. All other relevant materials can also be milled or ground to a high quality on this machine system.

"Zero point clamping system is my favorite feature – quick, precise, and makes milling projects so much more enjoyable."

"Just keep going on! imes-icore is actually the perfect choice you can have in the dental market to comine perfection, precision an finally the best results all together."

"CORiTEC is the best! The system consistently impresses me with its high quality, superb organization, and outstanding performance."

Find out how customers worldwide benefit from the precision and innovation of our CAD/CAM systems.

"Zero point clamping system is my favorite feature – quick, precise, and makes milling projects so much more enjoyable."

"Just keep going on! imes-icore is actually the perfect choice you can have in the dental market to comine perfection, precision an finally the best results all together."

"CORiTEC is the best! The system consistently impresses me with its high quality, superb organization, and outstanding performance."

![]()

post-processing of 3D metal prints

Hybrid processing as a competitive advantage.

As a specialized solution for post-processing metal 3D printed parts, the CORiTEC 650i PRO series combines additive and subtractive manufacturing. A technological advantage that sets your lab apart from the market.

| ✓ | Compatible with all common metal printing systems |

| ✓ | Post-processing of metal prints (e.g., LPBF or laser-sintered metal frameworks) |

| ✓ | Hybrid machining of 3D-printed metal plates, e.g., model castings and telescopes |

of 3D metal prints

Hybrid processing as a competitive advantage.

As a specialized solution for post-processing metal 3D printed parts, the CORiTEC 650i PRO series combines additive and subtractive manufacturing. A technological advantage that sets your lab apart from the market.

| ✓ | Compatible with all common metal printing systems |

| ✓ | Post-processing of metal prints (e.g., LPBF or laser-sintered metal frameworks) |

| ✓ | Hybrid machining of 3D-printed metal plates, e.g., model castings and telescopes |

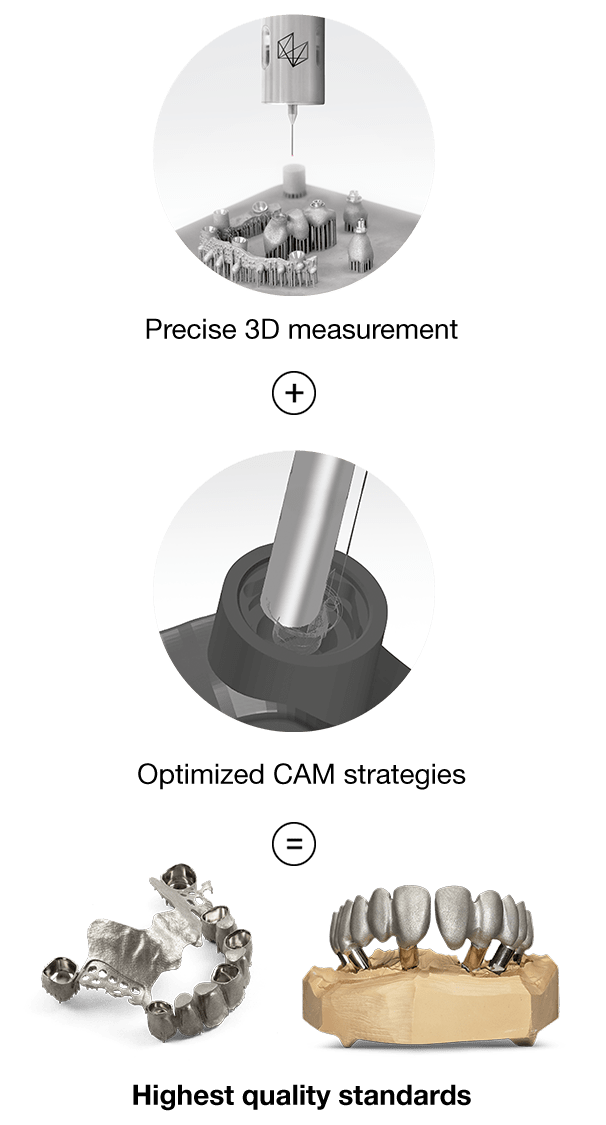

| Precise 3D measurement |

Optimized CAM strategies |

|

Highest quality standards |

|

|

|

|

A safe investment in the future.

A safe investment

in the future.

Contact us

| Contact us conveniently by e-mail or via our contact form – we will help you quickly and reliably with any questions about our products, services or technical concerns. |

Download Center

| Are you looking for marketing, service or sales documents? In the Download Center you will find all important documents quickly and clearly under the relevant heading. |

Product Guide

| Are you looking for a milling machine? Our product guide – consisting of selector and configurator – helps you to find the optimum CAD/CAM system quickly and easily. |

Newsletter

| Subscribe to our newsletter and receive regular exclusive updates, useful expert tips and the latest information on products, services and events. Let's go! |

Contact us

Contact us conveniently by e-mail or via our contact form – we will help you quickly and reliably with any questions about our products, services or technical concerns.Download Center

Are you looking for marketing, service or sales documents? In the Download Center you will find all important documents quickly and clearly under the relevant heading.Product Guide

Are you looking for a milling machine? Our product guide – consisting of selektor and configurator – helps you to find the optimum CAD/CAM system quickly and easily.Newsletter

Subscribe to our newsletter and receive regular exclusive updates, useful expert tips and the latest information on products, services and events.Let's go!